The top version has a black PVD coating. The laser engraved logo identifies this knife as one of the 25 made for the A.L.T.A. chapter based in Trieste.

The most distinctive detail is undoubtedly the strong upper quillon, which had the dual function of stopping the blade when stubbing, and to offer adequate support to the thumb.

The handle ends with a triangular tip. Although it can be used as glassbreaker, it was designed for close combat.

From above, the three options available: camo coating, Top Black PVD, beadblasted. The knife in the center is the one I used regularly for years. Despite the intensive use, it's still in excellent condition.

The Cordura sheath made by Vega Holter was designed for the leg carry, however, the large number of additional loops allows many alternatives.

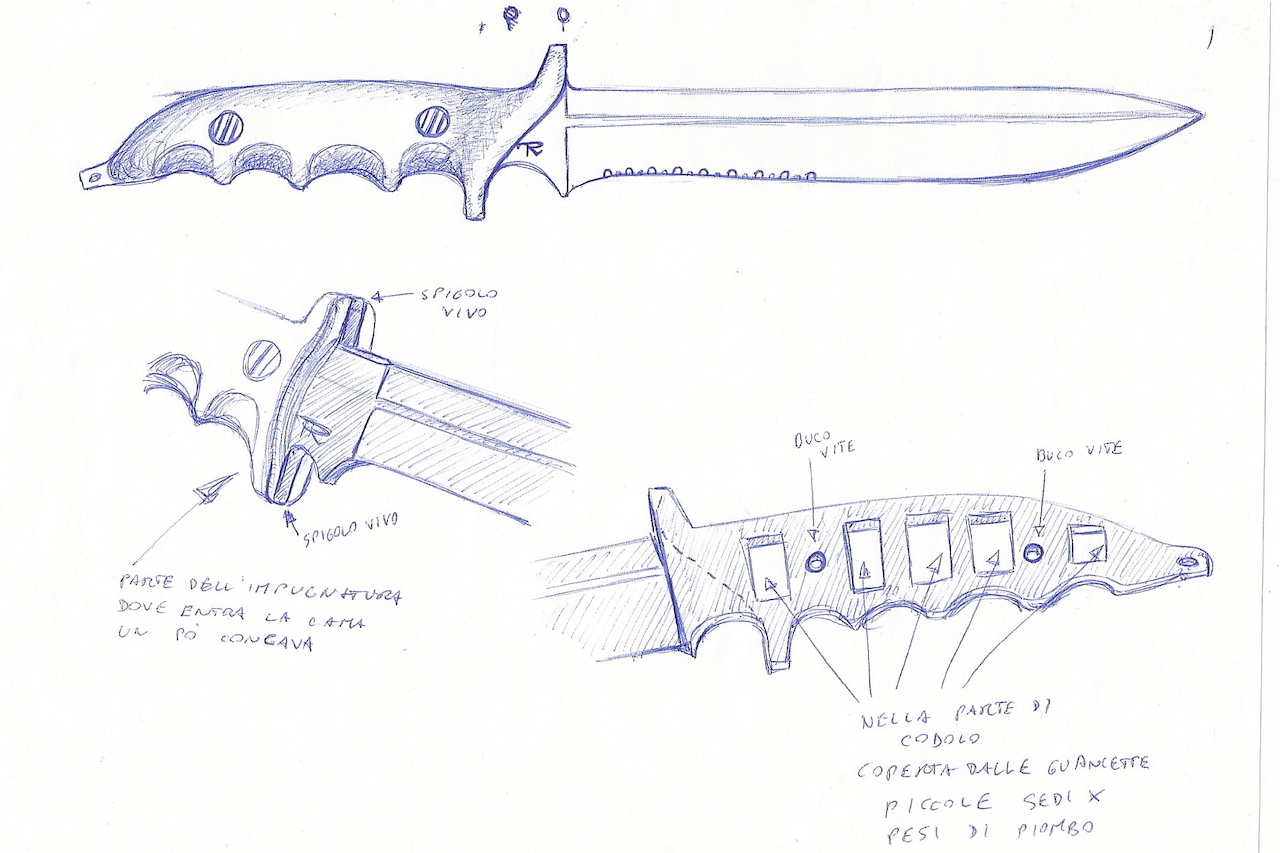

The first sketch.

From above, the first four models used for development of the Fearless. Note that most of the changes have affected the handle, while the blade design has changed little.

From the top: an ergonomic study that helped me improving the ergonomics, a version without the upper quillon more suited for field use, then set aside, and the two final mockups. The penultimate is quite consumed due to sparring.

A series of lucky events

The Fearless was my first design that came to production, presented al pubblico during 2006 edition of EXA Show, Brescia, that was the main Italian exhibition until 2013.

When I started working on it, I wanted to create a hybrid between a combat knife and a field tool, offering the best compromise between the two. Once arrived at the final design, I would have commissioned a craftsman. But things turned out very differently: at the time I was writing to the forum Collini cutlery in Busto Arsizio and I became friends with the owner, Rudy, and his collaborator Davide. After seeing the project, still in course of development, they encouraged me to contact a manifacturer based in Maniago, particularly Viper, who was looking for a similar product. After our first meeting Giovanni Miniutti, one of three partners of the company, decided to believe in the project, which was then produced in 330 specimens, giving way to my career as a designer.

Fearless, in name and fact

The name “Fearless” was perfect, since at the time that knife was innovative in many respects. First of all, since it wasn’t designed for mass production, I had developed it regardless of market trends, focusing only on what I considered fundamental attributes. Also, it was the first knife of this type made by Tecnocut, best known worldwide with the Viper brand, which until then had focused on elegant knives, never on military ones. The company decided to enter that branch in its own way, with an attention to details unusual for tactical knives, using materials and treatments that would have had a wide circulation only years later. Furthermore, the price was very affordable, given the general characteristics.

A long development

A long development

Combat knives are a sensitive issue: it’s easy to be misunderstood and accused of inciting violence. I have deep respect for life, but the reality shows daily as the use of lethal force is too often still required. While waiting for the day when we no longer need weapons for our safety and security, it is good that those who are forced to use them have instruments as effective as possible. Consider then that my Fearless is not a tool that will end in the hands of the occasional criminal, who prefer the cheap kitchen knife taken at the supermarket, but rather in those of police or military operators.

After this premise, there are basically three reasons why the project was born with single edge, and with asymmetrical handle: the first is that the best double edged fighter was, and still is, the Applegate-Fairbairn, the second is that I wanted the Fearless to be also suitable for field tasks, the third is that double-edged knives are illegal to carry in Italy.

The development was long and complex: from the study of numerous texts on knife fighting, forensic medicine and anatomy, as well as from my experiences in martial arts and with knives, I developed various designs, translated into wood models to check the ergonomics. Before starting the production, Viper realized a steel prototype and we perfected weight, balancing and robustness. The first wooden prototype is dated May 12, 2004, while the virtually definitive one is dated April 7, 2005.

Unlike other fighter-utility knives, the Fearless was not designed for a specific style of fighting, but to better adapt to the user’s one, providing a firm grip, agile, and the maximum blade control. It doesn’t need to be explained to be fully exploited: the trained user finds the right feeling as soon as he grabs it.

One blade, three colors

Along with the manufacturer, we decided to use the Böhler N690 Co, who was then a new material, which was launched by the Extrema Ratio production, characterized by excellent cutting ability and high rust resistance. Many over the years have denigrated this material branding it as weak performer, whereas they should have blamed the incorrect heat treatment to which certain producers subjected him: if well-tempered, it offers remarkable performances.

On the market were proposed three different versions: the entry level had beadblasted finish, the middle was covered with a camo coating, and the top one had a PVD (Physical Vapor Deposition) coating, very advanced for its time.

As said, the blade is single edge, to be more usable in the field, since you can place your weak hand on the spine. The double hollow bevels make it extremely sharp and light, yet robust thanks to the center rib than is six millimeters thick. The spear tip ensures good penetration and all the necessary strength, while the slightly inclined edge prevents the blade from sliding when cutting. The reasons for the small width and rhomboid section are obvious for anyone who has the slightest smattering about martial use of the knife. During the years I was able to submit my knife at very demanding uses, sometimes real abuses, and never able to put it into crisis.

The best handle

At the time I did not give any weight to aesthetics, focusing on other more important features: after all the Fearless was designed to be my knife. Fortunately the audience really liked the final result.

The construction is full tang, with Micarta scales (unalterable synthetic material, made from cotton layers and resin) fixed by two pairs of socket head screws. The special Micarta used by Viper was absolutely innovative in 2006, so that only seven or eight years later began to spread in custom knives and industrial ones; its particular texture, characterized by an unusually large plot, offers a better grip, without the need for surface textures. With the use of this material it tends to get dirty and darken, but wash it with soapy water is enough to restore its original appearance.

The handle of the Fearless had to communicate immediately the orientation of the edge, provinding a strong and secure grip, and at the same time allow a fast, natural riding, instinctive, both in the hammer grip, than in the saber or ice pick ones.The two guards have two distinct conformations due to the different functions. The lower one keeps your fingers away from the edge, while the upper one stops the thrust of the blade and has a knurling where to put the thumb, in order to vary the inclination of the knife respect to the wrist, when stabbing.

Under scales, the tang is lightened to contain the final weight and perfect balance; for the same reason the thickness of the whole part within the handle is reduced to 4 millimeters, and this causes the front part of the scales to be recessed, so nothing can slip below, lifting them. The center of gravity is in correspondence with the index groove: the knife is free from inertia, always controllable when changing grip or direction. The handle ends with a rear, triangular point so as to discharge all the energy in a very small surface, in line with the handle and distant from the hand. Although it can be used as glassbreaker, it was studied for use in CQB on muscles, joints and pressure points. Inside is a triangular opening, to which you can attach a lanyard.

All of the tang edges are rounded, with an attention to details simply unsual for tactical knives at the time, which instead was normal on the gentleman’s Viper folders.

Sheath by Vega Holster

The knife is accompanied by a multi-sheath also of my project, made in Cordura by Vega Holster, already at that time a leading manufacturer of holsters and tactical gear. The rigid core prevents the blade from slicing, while the retention is performed by two straps with snap button. In front there is a magazine pouch, secured with MO.L.L.E. system (Modular Lightweight Load-carrying Equipment) useful for storing a stone or a multitool, and easy to remove if you prefer to save space. The system is designed for leg carry, with openable belt loop and removable leg strap, but the numerous MO.L.L.E. attaching points allow different configurations, or to integrate the scabbard on backpacks or tactical vests

Special versions

With just 330 units made, the Fearless was a limited edition. However there is one even more rare version, produced by the Collini cutlery in just 25 units for the section of A.L.T.A. (Association of retired Amphibious Troops) based in Trieste, thanks to a very dear friend who is part of it. This particular edition was only with PVD coated blade and was distinguished by the association’s logo laser etched near the guard and, on the other side, the progressive number.

Current price

The price, when the knife was presented, was about € 160,00 for the sandblasted version, € 170 for the camo coated, and € 180 for the top black PVD.

The listing flea does not exist, since in all these years I have seen only two for sale, both gone in a few hours. Certainly the interest is still alive, since I often get inquiries about, especially by foreign fans that at the time, when the Italian cutlery was much less present on the international market, didn’t know of its existence. Unfortunately, unless you find a copy in some forgotten in a small knife shop, finding a Fearless is now almost impossible. A new edition is not planned, and the advanced version, the Fearless II, never passed the prototype stage.

Specifications

Manufacturer: Viper by Tecnocut

Web: www.viper.it

Model: Fearless

Blade steel: Böhler N690 Co 58-60 HRC

Handle material: Micarta

Overall length: 296 mm

Blade length: 152 mm

Blade thickness: 6.1 mm

Weight: 262 g

Sheath: Cordura by Vega Holster